This build is actually a project that I am doing for one of my two wholesalers. Both are greatly into bikes, mopeds, karts, racing, drag races and so on. As I've been building several bikes for show-purposes, such as my Sprocatti project bike, they wanted me to build one for them.

I will be taking this bike to numerous shows around Europe. We'll most likely be racing it too!

It all started with the frame. I've basically done the same thing as with my Sprocatti Project bike - I took off all the (useless) brackets and mounts. These are meant to hold brackets, fairings, fenders, side panels and what nots into place - USELESS when building a show bike.

Above shows the before and after result of the frame in general. The paint is actually a customised pearl green with a bit of a flip flop effect added to it. I must add, however, that it looks a lot better in real life and light than on pics!

Here's a nice touch we added to the seat pan:

- We've taken a small (160mm long) shokabsorber. This shock was actually meant for minibikes or mountainbikes, but we thought it would look cool as a seat pan spring - and it does.

If you're wondering, the seat pan isn't dusty, it's also a flip flop effect that was powdercoated. Powdercoated black with a clear varnish that has flip flop sparkles in it, so to speak. Again, this pops a lot more in real lighting - the pics don't do it justice!

Heart of the Lion

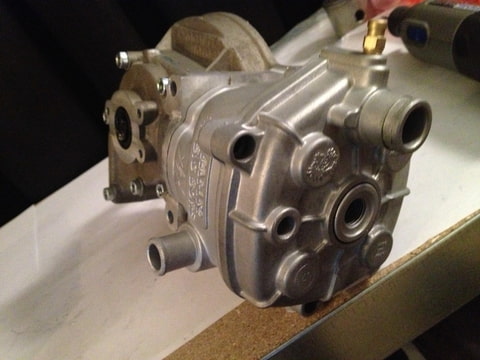

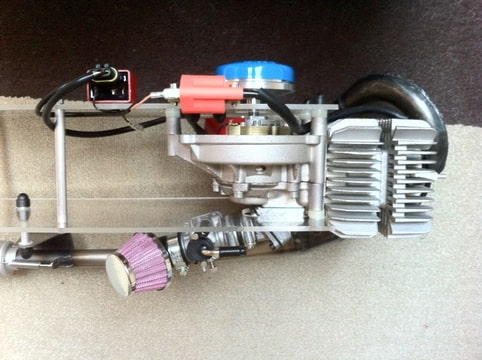

Now, let's go to the heart of this beast, you've guessed it, the 2007 NEW TYPE Simonini Engine. We didn't leave this stock either. I must say, even though I am a huge fan of Simonini and sell their parts on a daily basis, Simoinini totally lacked precision when it comes to the general idea of this engine. Sure, the porting in the cylinder is huge and fabulous, but the ignition and cylinder head are what strikes me as weak and unfinished.

Cylinder head

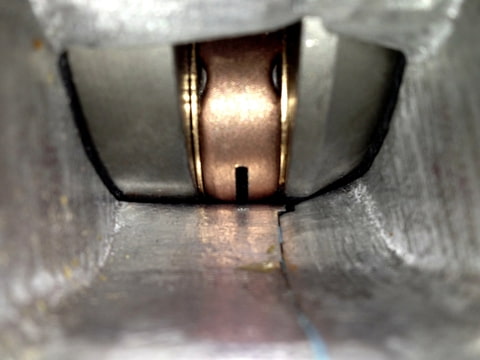

Let's begin with the cylinder head. The head has no decompression kit/valve. This will make it impossible to start as push-starting it won't work, pedal starting it won't work (no pedals, this is a show bike) and pull starting it sounds decent but still not favorable for a show and race bike.

Solution? Build a decompression valve in your current head, OR, take a Honda Hobbit/Camino/PA50 cylinder head. Obviously, as only the stock (50cc) heads come with a decompression valve, and the FastArrow 46mm heads which are hard to find, you'll have to mill the combustion chamber of the cylinder head to 47.6mm. Pics to follow and thanks Terry for the tip!

Ignition

As we are criticising this engine, I would like to turn your attention to the ignition system. The instruction booklet, or should I say single sided piece of paper, that came with the ignition system in the complete kit is a big laugh. The drawings look like they were sketched by a small child! Not to bother though, I guess the Italians didn't want to use computers to animate their instruction booklet/piece of paper, but at least do some effort guys - we are paying top bill for this engine so we expect something in return!

Let me put it to you this way; this engine goes for around 900 to 1200 euros depending on where you buy it. People who are willing to spend such a large amount on a little Vespa/Piaggio engine are most likely also willing to spend a couply hundred more on a decent ignition system. Therefore, in my opinion, Simonini should have brought out this engine with a fitted internal rotor ignition if you ask me - a HPI 2007 Internal Rotor Ignition would suffice, I'm guessing!

And what I'm guessing is what you're guessing - we are fitting a HPI 2007 Universal Internal Rotor Ignition on that little Simonini engine. Why? Because we can and it's a must if you think about it. The stock ignition will most likely blow after a certain period of time at high RPMs, whereas the internal rotor ignition can easily handle 20000 RPMs without a problem - not that we will be able to rev it to that point, but whatever!

I've customised a stator plate for the engine two days ago and the HPI stator fits like a charm. Maybe we will be machining these plates/adaptors on a CNC-machine to resell them on our webshop, maybe we'll even sell complete HPI ignition kits with these stator plates/adaptors for the Simonini engine on our webshop! Who knows :).

The only thing we still have to do regarding the ignition is adjusting a HPI Rotor to its exact conical position. We may drill out an already existing HPI rotor and custom fit a conical instert (according to the crankshaft's measurements) or we will have HPI supply us with a non-pressed rotor that we can insert our own conical press into - Option two is what we are leaning toward.

Exhaust

And again, as stock exhausts on a complete engine kit as these are great, we felt that we needed to do something slightly different.

The name is Fabrizi and these are rare - hence why we want to use this exhaust both for show and race purposes. We always have the ''stock'' Simonini exhaust that came with the kit to fall back on.

How do you stop at full speed? Is what I hear you ask.

And, of course, disc brakes are the answer. This time, we're going another route - a more slim and sexy route if you will. Instead of using thick and big discs and calipers off a scooter, we will be using mountainbike disc brake systems both on the front and rear wheel.

These babies come with 6-piston calipers and 203mm Wave Discs - not bad at all!

We are nearly finished with the rear wheel's disc brake system - Pics to follow.

We had to machine our own wheel plate with bearing to hold the whole system together on the rear end in the cradle/subframe (pics to follow). All that is missing is a bracket to hold the caliper.

The front wheel will be milled out on the opposite side of the brake-hub. We will then fit a solid cylindrical milled aluminum piece and press fit it into position. Then, we will mill a 12mm diameter axle. All this rotates around two 2ZR bearings pressed into place in the adaptors.

Thanks for reading so far and make sure to keep checking us out as we try to update on a daily basis!

- Fred